How to Control Analog Gear Remotely

This article explores how to combine the MIDI protocol with a microcontroller and an Ethernet LAN for remote control of analog gear.

Intro

Part I

Automation in audio production involves making changes automatically, such as adjusting volume levels, throughout a song. With automation, you can instruct your Digital Audio Workstation (DAW) to turn effects on or off, change volumes, pan positions, plugin settings, and effect levels during track playback.

Evolution of Automation and Analog Recording

In the past, producers made manual adjustments during the final mix of a track. Today, DAWs enable automatic adjustments, allowing for multiple simultaneous automations that can be endlessly repeated. Automation can be recorded in real-time or drawn into the DAW, controlling parameters of the DAW or plugins. The DAW records these changes and repeats them during playback, eliminating the need for recall sheets as all parameters are saved.

Extending Automation to Physical Devices

Extending automation to physical analog devices in the studio, such as hardware units, has been implemented by some companies through dedicated plugins. While beneficial, this approach has drawbacks including additional plugins, protocol complexities, physical wiring, and costs associated with software development.

Pros and Cons of Remote Automation

Pros:

- Streamlines automation processes.

- Enhances precision and repeatability.

- Integrates seamlessly with DAWs.

Cons:

- Plugins: Require installation, adding complexity to the DAW interface.

- Protocol: Necessitates protocol drivers, increasing CPU load.

- Wiring: Involves physical connections, often using cables for noise-free operation.

- Cost: Involves software development expenses.

Despite these drawbacks, there are solutions for effective remote unit management.

Optimizing Remote Management with MIDI and Ethernet

MIDI Protocol:

A simple solution involves using the MIDI protocol for automation. MIDI can send/receive notes and commands, making it versatile for various devices, including guitarist pedalboards. DAWs natively support MIDI, facilitating integration and synchronization with audio tracks.

Ethernet for Extended Connectivity

MIDI signals can be transmitted over USB or Ethernet. Ethernet offers the advantage of longer cable lengths without the limitations of USB. The rtp-MIDI (Real Time Protocol) enables MIDI over standard networks, including Ethernet and Wi-Fi, which is supported by most modern devices.

Implementing MIDI over Ethernet in the Studio

Point-to-Point vs. Networked Connections:

Traditional studio setups involve direct connections between devices, such as microphones to preamps. However, MIDI over Ethernet allows for networked connections using an Ethernet switch, enabling multiple devices to communicate simultaneously.

Scalability and Expandability

Ethernet can handle numerous MIDI channels over a single cable, making it infinitely expandable. Unlike USB/DIN-MIDI, which is limited to 16 ports per cable, rtp-MIDI networks can support unlimited virtual ports, enhancing scalability.

Addressing Drawbacks

- No additional plugins: DAWs can manage MIDI commands directly.

- No extra drivers: DAWs have built-in MIDI support.

- Wiring flexibility: Ethernet cables can extend beyond USB/DIN-MIDI limits, and Wi-Fi can be utilized.

- Cost-efficiency: MIDI is a global standard, eliminating extra software development costs.

Hardware and Software Guidelines

Part II

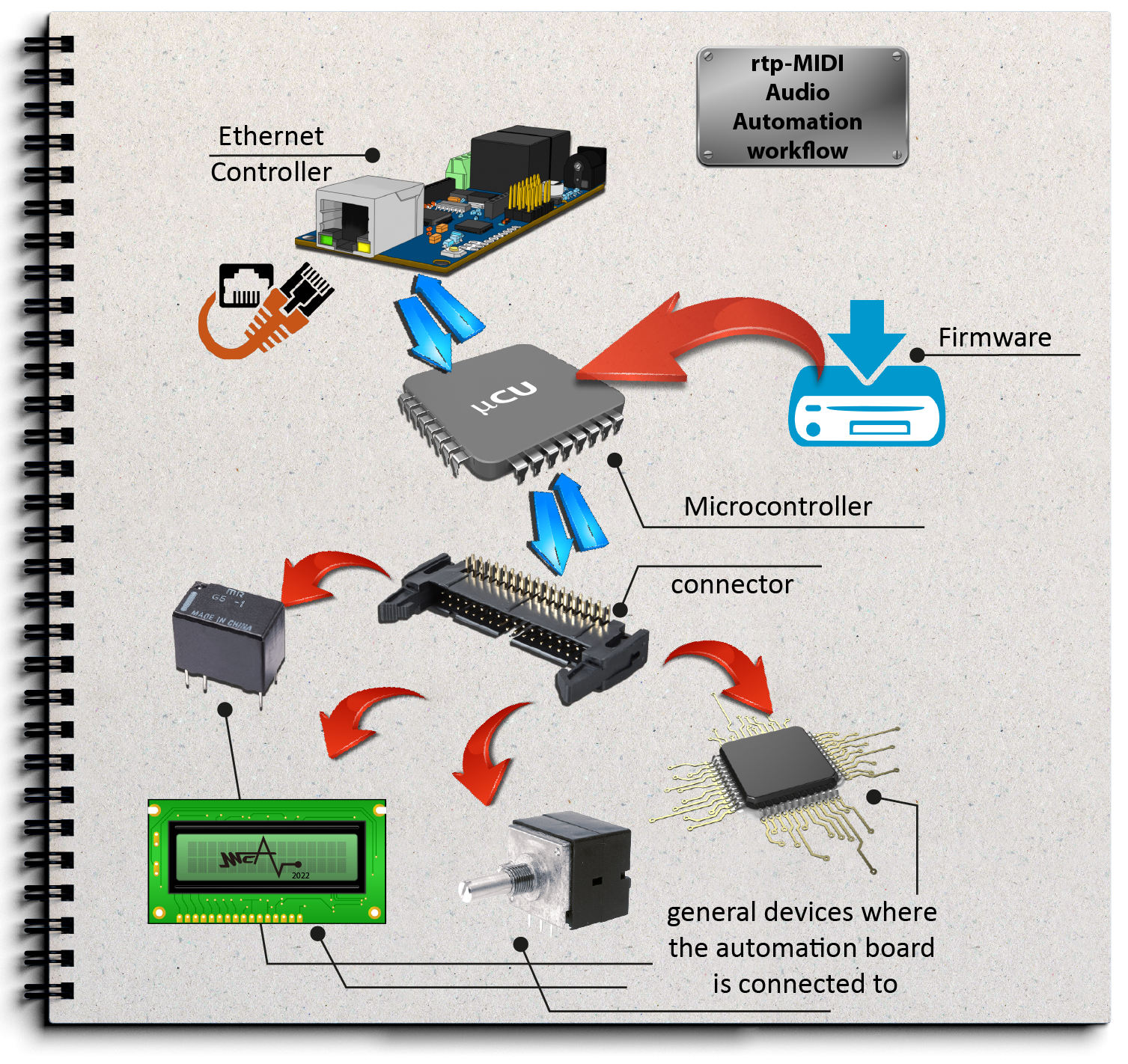

Develop an embedded automation board for audio device control focusing on:

MIDI Information from LAN: Interface MIDI devices with LAN to avoid long DIN/USB-MIDI cables.

Decoding MIDI Messages: Use a microcontroller (MCU) to decode MIDI messages for audio automation.

Controlling Devices: The MCU controls electronic devices such as motorized faders, DACs, and relays.

A block diagram let you better understand each single step. The boards includes all electronics components. The RJ45 ethernet jack connector is provided. The connection to the audio device take plase by a board-to-board or cable-to-board connector

Board Design

The board should include an Ethernet controller and an MCU, minimizing RF noise to ensure transparency to audio signals.

Firmware

The firmware should be open source and adjustable to different hardware needs, promoting a flexible and educational project.

Ethernet Controller and Connectivity

The Ethernet controller, like the WIZnet W5100, facilitates easy network connections with minimal components. The communication between the Ethernet controller and the MCU uses the SPI protocol.

Using the Project

MIDI Audio Automation separates digital control from analog domains. The project, available as hardware and software, is open for customization and use by both DIY enthusiasts and professional audio companies.

Conclusion

Part III

Remote control of analog audio gear through automation and networked MIDI is a viable and scalable solution. By leveraging open-source hardware and software, this approach offers flexibility, cost-efficiency, and enhanced control over studio environments

MIDI Audio Automation: Digitally Controlled Analog Equipment

MIDI Audio Automation involves digitally controlling analog equipment. It’s crucial to emphasize that digital and analog domains remain completely separate. Analog equipment can have its various parameters and functions altered by a digital control system. Essentially, the digital aspect replaces manual adjustments, such as turning a knob or activating a switch, while the analog components continue to operate as intended.

Separation of Digital and Analog Domains

In this system, digital control does not alter the inherent nature of analog equipment. The analog components retain their original characteristics, ensuring high-quality audio output. Digital control merely provides a more efficient and precise way to manage these analog parameters.

Open Source Hardware and Software

Both the hardware and software involved in this project are open source, making them free to use, embed, copy, and customize. The entire project includes physical hardware, software code, schematics, and Gerber files, providing a comprehensive toolkit for DIY audio enthusiasts and professional audio companies alike.

Empowering the DIY Audio Community

The rtp-MIDI Audio Automation project is designed to inspire the DIY audio community, encouraging users to embed new features into their own audio designs. The project is accessible to all, regardless of whether you are an individual hobbyist or a professional audio company.

Acknowledgment and Ethical Use

Regardless of how you use the project, it’s important to acknowledge MCAudioLab and this article when sharing your work on the web and social media. This recognition supports the ongoing development and sharing of innovative audio automation solutions.

In Summary

MIDI Audio Automation bridges the gap between digital precision and analog quality. By leveraging this open-source project, you can enhance your audio equipment’s functionality while maintaining the integrity of analog sound. Join the community of audio innovators and contribute to the evolving landscape of audio technology.

Resource Lists

MIDI: https://en.wikipedia.org/wiki/MIDI

rtp-MIDI: https://en.wikipedia.org/wiki/RTP-MIDI

Microcontroller: https://en.wikipedia.org/wiki/Microcontroller

Atmega2560: https://www.microchip.com/en-us/product/ATmega2560#document-table

WIZnet W5100 https://www.wiznet.io/product-item/w5100/

All trademarks mentioned in this page are used for identification purpose only and are properties of their respective owners.